MPS粒子法を用いた

最先端の流体解析シミュレーション

MPS粒子法を用いた

最先端の流体解析シミュレーション

MPS粒子法を用いた

最先端の流体解析シミュレーション

MPS粒子法を用いた

最先端の流体解析シミュレーション

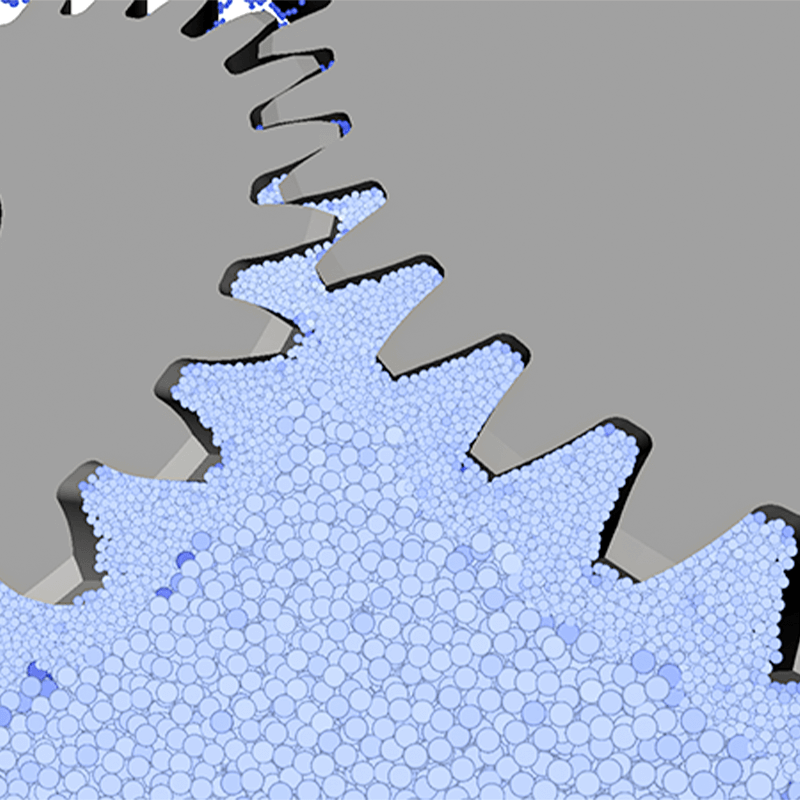

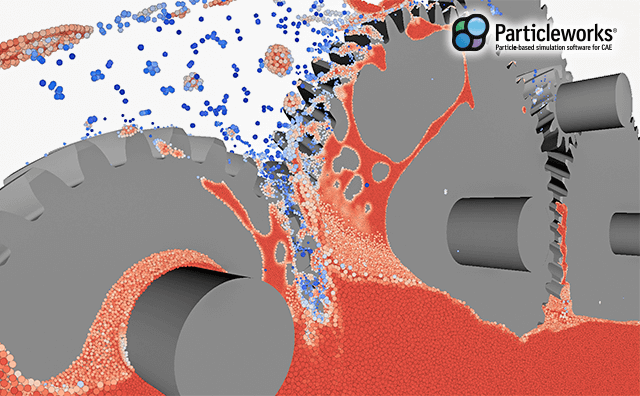

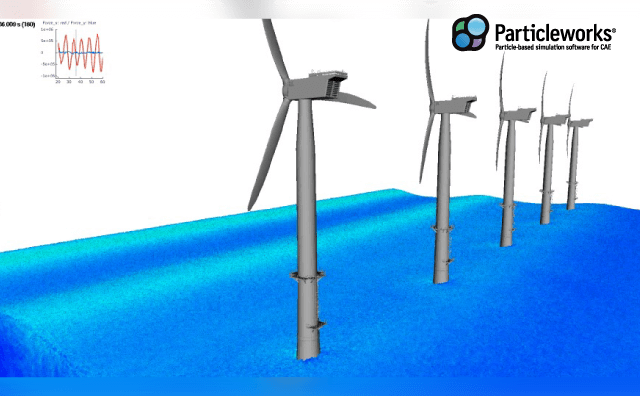

The MPS (Moving Particle Semi-implicit) and SPH (Smoothed Particle Hydrodynamics) are two common particle-based fluid simulation techniques. MPS excels in stable simulation of free surfaces with large deformations and interactions with structures, while SPH is known for its ease of implementation. Particleworks uses the MPS method to accurately and stably simulate highly deformable fluids like water and oil. It is designed for design evaluation, product development, and academic research.

Time-saving simulation method

without mesh generation

High-accuracy simulation

for fluid deformation

High-scalable GPU computing

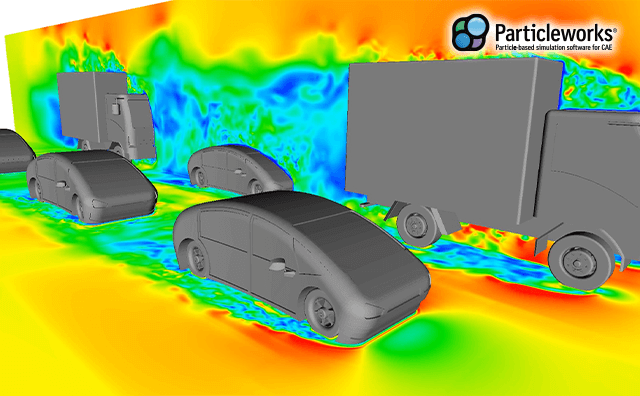

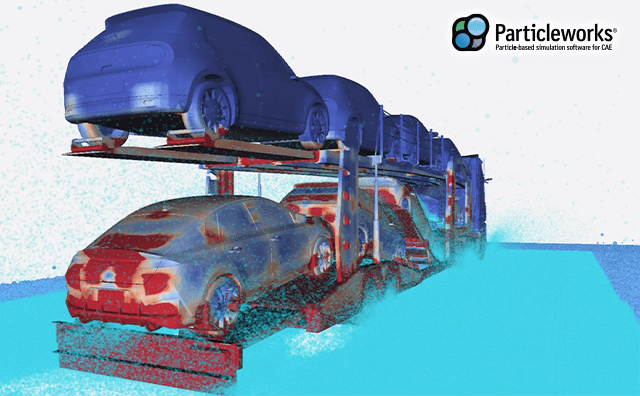

Simulates gas-liquid flow considering airflow and water splash for vehicle driving.

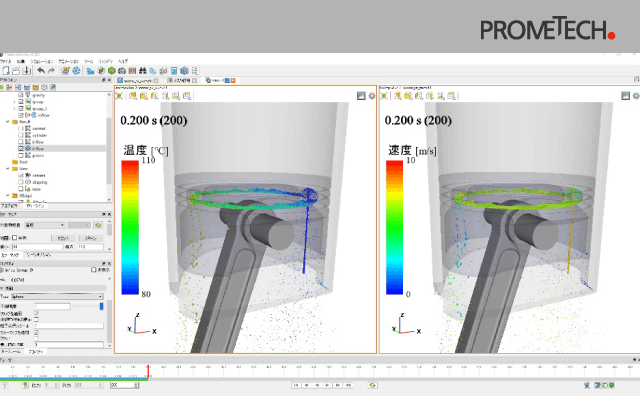

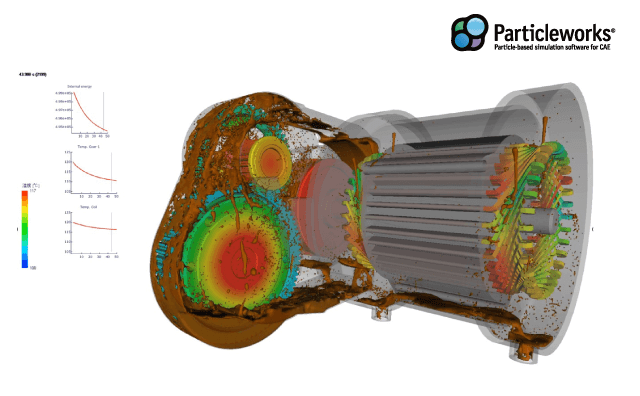

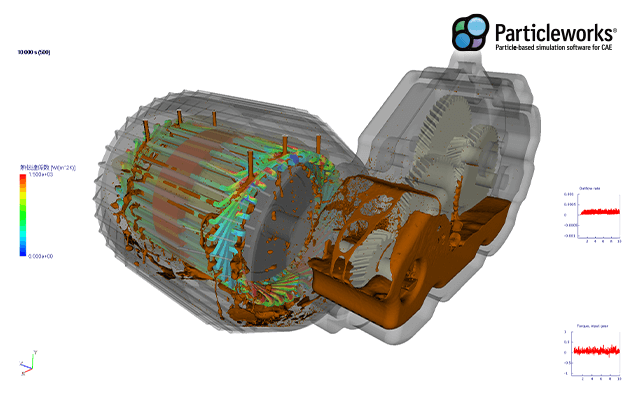

Evaluates motor cooling capability by simulating fluid-structure heat transfer and oil behavior simultaneously.

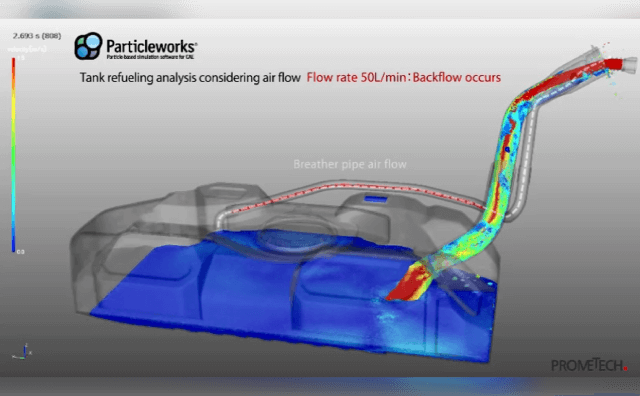

Evaluates fuel tank sloshing by considering the behavior of air and fluid surfaces with large deformations.

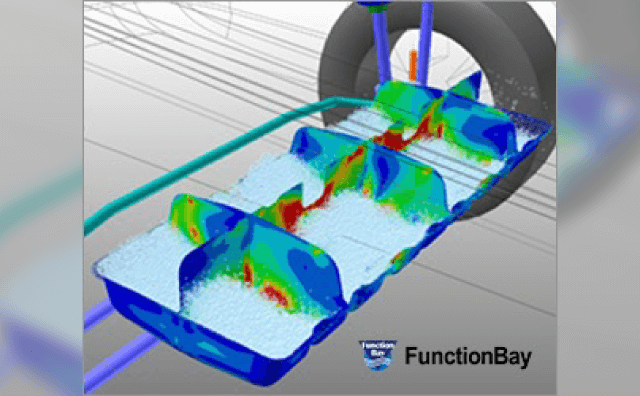

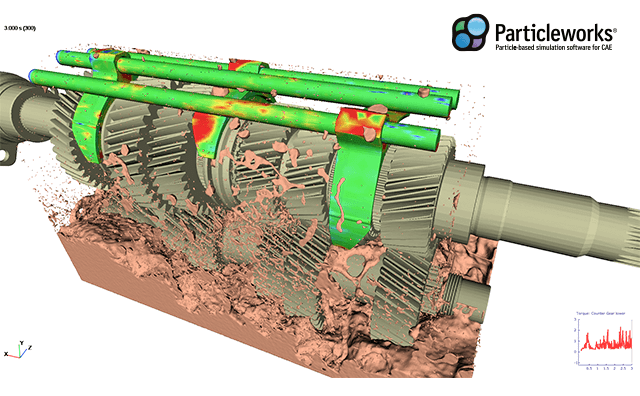

Simulates and evaluates oil behavior and torque in a gearbox that is very difficult to see inside.

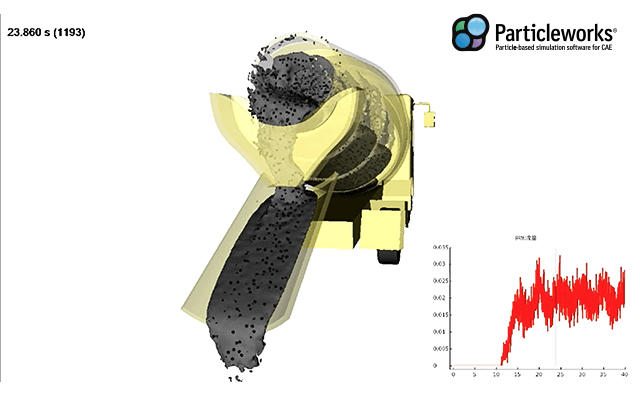

Simulates and visualizes mortar and aggregates to evaluate viscosity and shear rate.

Simulates load and sea surface behavior caused by wave interference with offshore structures.

If your company is considering optimizing the operational costs of Particleworks or Granuleworks, we highly recommend evaluating our cloud-based solution, Prometech Cloud.

For companies planning to begin simulation or expand its usage, the upfront cost of high-performance hardware is often a major hurdle.

With Prometech Cloud, there is no need to invest in hardware. You can start using Particleworks or Granuleworks easily and affordably, without installation or setup—just run it from your web browser.

Prometech Cloud does not require license fees or annual support costs for Particleworks or Granuleworks.

Usage is simply deducted from the deposit you purchase. Deposits are valid for one year, making this system ideal for short-term projects or seasonal demand.

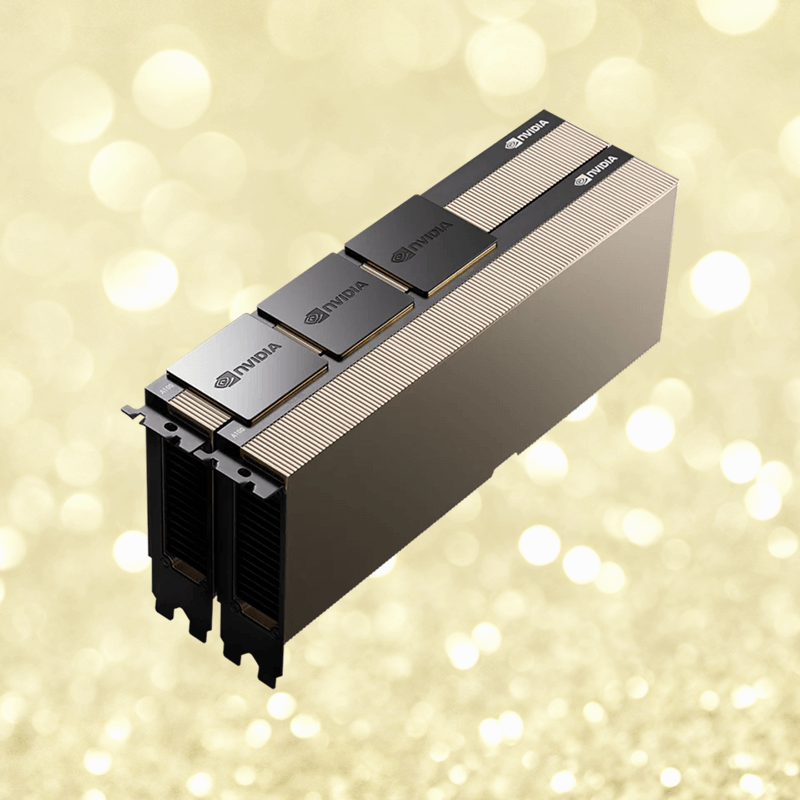

Simulation performance is key to unlocking the full potential of Particleworks and Granuleworks.

With Prometech Cloud, you can run simulations using up to 8x NVIDIA A100 GPUs, enabling large-scale, high-speed computations.

Experience the power of multi-GPU computing firsthand.

From cloud usage inquiries to software operation, settings, and even infrastructure and system-related questions—everything is handled through a single support contact.

You can use Prometech Cloud with full confidence, backed by our integrated support.

You can see videos including solution introductions and simulation examples whenever you like.